- United Kingdom

- Canada

- Spain

- Malaysia

- Netherlands

- Singapore

- United Arab Emirates

- Ireland

- Qatar

- United States

- Belgium

- Denmark

- Japan

- Estonia

- Romania

- Lebanon

- Oman

- Egypt

- Portugal

- Saudi Arabia

- Jersey

- Brunei

- Lithuania

- Austria

- India

- Israel

- Poland

- Latvia

- Turkey

- Kuwait

- Australia

- France

- Luxembourg

- Thailand

- Taiwan

- Germany

- Hong Kong

- Iceland

- Zambia

- New Zealand

- Nepal

- South Africa

- Philippines

- Switzerland

- Pakistan

- Sweden

- Uzbekistan

- Jordan

- Italy

- Hungary

- Malta

- Bulgaria

- Jamaica

- Bangladesh

- Mexico

- Guam

- Morocco

- Ecuador

- Slovenia

- Chile

- Slovakia

- Greece

- Panama

SEERS Medical design manufacture a wide variety of medical products on site in Debenham, Suffolk.

Framework is powder coated with an anti-microbial additive using a static charge, to ensure the paint is evenly distributed across the entire surface, preventing any excess build-up or uncoated areas. Frames are then oven baked to seal the paint prior to assembly.

Products are then assembled using high quality components from reputable suppliers including Ti-Motion, Linak and Stabilus. Nyloc nuts are used to prevent any bolts loosening in transit or when the product is in use.

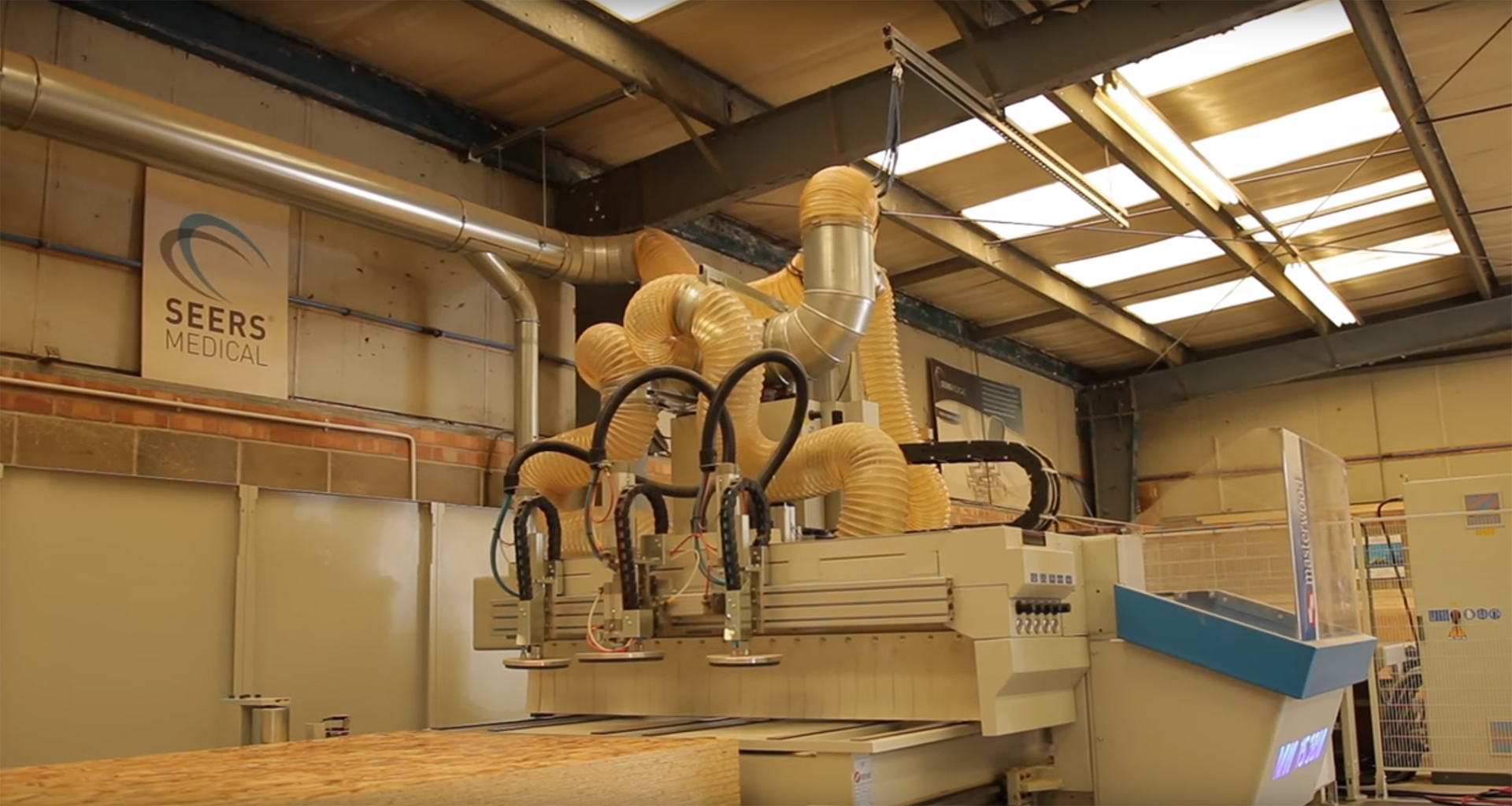

Wooden boards, manufactured from OSB, a much stronger material than MDF, are cut out using our on-site CNC Router.

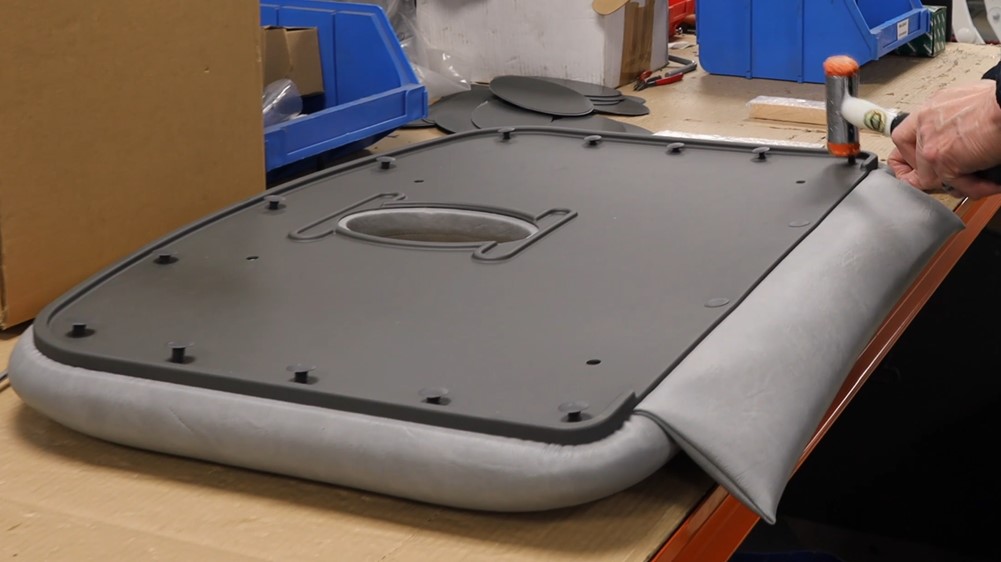

The wooden panels are then glued to 40mm virgin foam, and for some couches an additional 20mm of memory foam.

Vinyl shapes are routed through the CNC cutter, reducing waste and increasing repeatability. The wood & foam section is then encased within the vinyl shape using semi-automatic hydraulic presses, which are finished by hand.

Modern sections are finished with Easy Clean Upholstery backing, providing a large wipeable surface for user convenience.

You can find out more about our manufacturing process here: